SPORTENG are the leaders in the planning, design and construction phase monitoring of Fields of Play across the globe. Our team’s experience is unrivalled and we design high-quality Fields of Play for all levels of use and all surface types.

A baseball field is unlike any other field of play with its combination of different surfaces and a fixed element (Pitches mound) in the middle of the diamond with a significant vertical elevation from the surrounding area. The features of a traditional baseball field include:

The combination of the different surfaces and the elevated pitcher’s mound make it difficult to integrate a baseball field of play with other sports. But if your baseball field is for recreational purposes only, you can use a single surface type and a portable pitcher’s mound.

A softball field is similar to a baseball facility however doesn’t have the elevated pitcher’s mound meaning it can be more readily incorporated into a multi-use facility.

Our experienced team have delivered many baseball facilities and are well-versed with the requirements for different surfaces and the backstop fences and players dugouts.

Our technical expertise underpins all our projects, and we are regularly called upon to work on projects of high significance.

No matter if you’re a governing body or a local school, you will benefit from a sports field that puts the athlete first.

We guarantee that SPORTENG’s designs will meet your needs, while complying with WBSC standards.

SPORTENG projects run on time and on budget due to our team’s comprehensive 3D design work, exceptional engineering expertise, agronomic and irrigation consultation, along with clear on-site direction.

SPORTENG lives and breathes fields of play. We take our love of the game from the grandstand right into our office. We’re proud to Australia’s leading field of play design consultancy.

.webp?width=545&height=363&name=Baseball_DesignApproach_2%20(1).webp)

Our attention to detail is reflected in our mantra,‘measure twice, cut once’.

We’re dedicated to achieving the best results for your venue and its athletes, whether it’s a local legend or the next international star.

Here at SPORTENG, we pride ourselves on a reliable design process. The design process for a baseball and softball facility consists of the following key steps:

Optimize your synthetic grass Field of Play.

.webp?width=545&height=363&name=Baseball_Sustainability%20(1).webp)

%20(1).webp?width=545&height=411&name=Baseball_Sustainability_2%20(1)%20(1).webp)

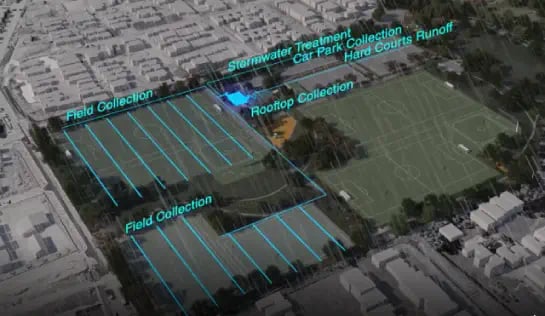

At the forefront of our design approach is sustainability. Not happy with just the status quo, we always strive to investigate new designs and construction techniques that deliver positive environmental outcomes.

We believe sustainability is intertwined with sports greatness.

As part of this, we integrate your requirements, from budget to performance values, through to sustainability practices – this ensures we achieve a successful result.

When considering the sustainability approach for a baseball or softball facility, we focus on the natural turf outfield and infield. For the natural turf areas, we:

When we design designing a synthetic grass surface, there are added environmental elements we need to consider and address in the planning and design process:

The SPORTENG team considers the whole-of-life cycle and the use of recycled materials at every stage of design and construction. We make sure that a sustainable end-product starts at the beginning of design.

.webp?width=545&height=363&name=Baseball_SurfacesOptions%20(1).webp)

The WBSC does not have specifications for the infield skin surface or the natural turf and synthetic surfaces. As baseball is played around the world, it is difficult to specify a granular product that could be readily available in each location. We’ve developed a specification for the skin material, as SPORTENG has worked with many local quarries.

There are several options that you can consider for the natural turf outfield. Unlike most other natural turf surfaces, the traffic across the natural turf playing surface is negligible.

All baseball surfaces for the facility infield and outfield are required to:

The backstop fence height is defined by WBSC to protect people who aren’t involved in the game. Some facilities also include a fly ball net, which prevents a higher percentage of balls landing on the field of play fenceline. The design of these backstop fences must integrate the player dugouts and accommodate local wind loads.

.webp?width=545&height=363&name=Baseball_Requirements%20(1).webp)

A correctly designed and constructed pitcher’s mound is made from clay bricks. The mound should be 10 inches (25.4cm) above the adjacent area to assist with fast pitches.

Both baseball and softball fields should include a granular ‘skin’ warning track at the interface between the field of play and the perimeter fence. The warning track alerts a fielder who might be staring upwards at a sky ball that they are about to run into a perimeter fence.

The options for a synthetic grass system can be influence by the reduced hours of use and reduced performance requirements for the surface.